Quality

Certified according to DIN EN ISO 14001 and DIN EN ISO 9001.

REISSMANN Sensortechnik has stood for quality for years.

High quality, traditional and personal with a global presence. All our products are subject to efficient quality methods and guidelines. We want to offer our customers quality, reliability and safety. We have introduced effective systems for quality management according to DIN EN ISO 9001 and environmental management according to DIN EN ISO 14001. As a medium sized company, we respond with the greatest possible flexibility to individual requirements and to self-evident quality standards. Using our imagination, a wealth of ideas, knowledge and experience, we will continue to work in a future-oriented manner to harmonise economic efficiency and technical progress with nature and the environment.

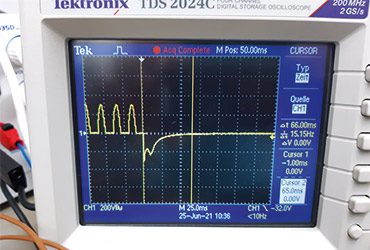

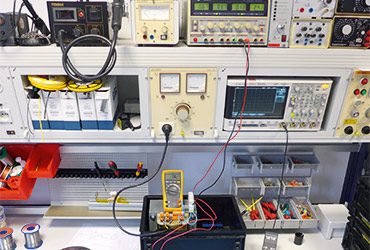

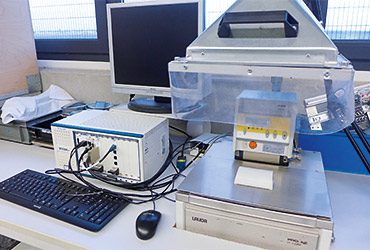

Test laboratory

Test and measurement equipment for all types of measuring resistors, for recording essential product parameters as a final quality test, guarantees our customers correct functionality in use.

For example, this would be the measurement of resistances as a function of changing temperature. The tests satisfy the requirements for use in measurement and control technology for machines and process lines.

We have developed automated programming and testing stations for our electronic device technology; these processes also ensure the highest possible, reproducible quality of our products.

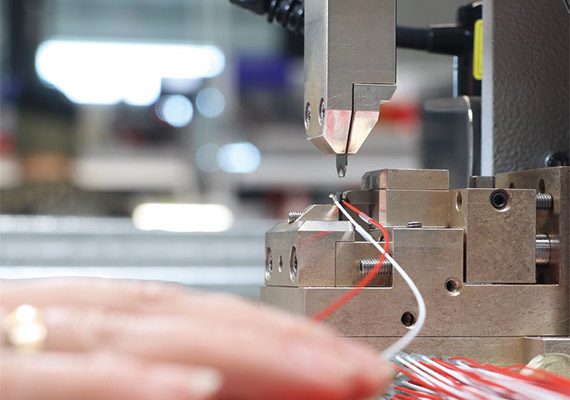

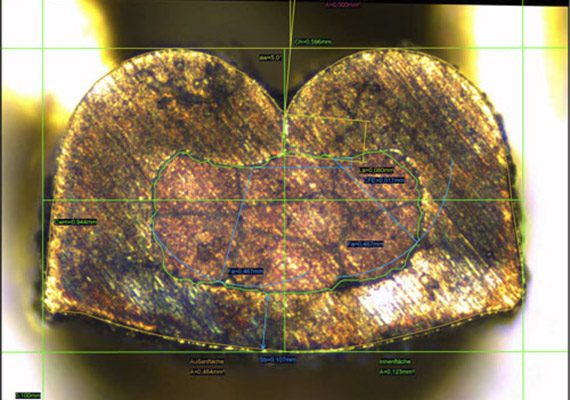

Microsection laboratory

In order to test in accordance with the high quality standards that you and we demand, we have expanded our measuring and testing technology to include a microsection laboratory. This enables us to test and document our connection technology at automotive level. We are also happy to offer this as a service for externally manufactured products.

ESD (Electrostatic Sensitive Devices)

The entire production and testing area is equipped and labelled as an ESD protection zone in accordance with DIN EN 61340. Electrostatic conductive floor coverings and furniture systems, centrally earthed, prevent electrostatic damage to goods at risk.

The earthing concept also consistently includes all individuals present in the correspondingly marked areas.

Regular checks, performed with appropriate measuring equipment, ensure the effectiveness of these facilities and systems. Ongoing training courses keep the qualifications and expertise of employees in these sensitive production and QA areas up to date at all times. The quality assurance concept also integrates those stations that follow the final inspections – with appropriate storage facilities, packaging materials, transport and dispatch equipment.